The Fifth S – Sustain There are three primary ingredients for achieving sustainable results. The first is keeping your ego and arrogance in check, the second is your relentless focus on adding value, and the third is becoming a continuous optimization master. Stay grounded Humility coupled with cautious confidence rather than arrogance is the best balance. I want to highlight that there is no room for arrogance in business, regardless of anyone’s cultural background, status, or upbringing. Celebrating your successes is entirely understandable. Take an hour or two or even a day or two, but get back to focusing on building a solid foundation for your business. You’re in a service business regardless of status, gifts, wins, or privileges. Your service should deserve recognition from the majority at all levels, from doorman to board room. I’m saying majority because nobody is on this earth to make 100% of the population happy. Besides, this is not a popularity contest. Be mindful of your efforts as to how they’ll benefit what population. Past successes are not proof of future successes, nor are past failures necessarily future ones. Every day is new, and you should be open to new possibilities. Life may change on a dime. The critical questions you need to ask yourself:

Keep your customer-centric focus. During our first S - Strategy, you’ll remember the importance of keeping customer-focused (product) marketing at the center of your business. You need to continuously assess the strategy from the perspective of a competitive advantage in a fast-changing environment. The key questions here are:

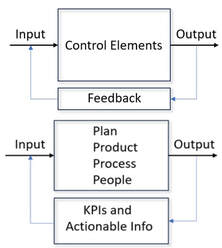

Become an Optimization Master The last ingredient to sustain results is based on Electrical Engineering Control Systems. In a Control System, there is an algorithmic relationship between input and output where the magic happens. Well… it’s not that magical … it’s about controlling the variables called Control Elements. Some people in the business call it “pulling the right levers.” Your fundamental Control Elements (levers) can be summarized as Plan, Product, Process, and People. You'll deliver results by making all the right decisions with sensible priorities on these four elements. However, this doesn’t mean it’ll be sustainable. However, what you do with the feedback loop in a control system will determine its sustainability because you’re optimizing the outcomes. This is where you continuously monitor, assess, and make decisions or corrections on the variables and their priorities. You utilize KPIs and other metrics as part of this feedback loop. In short, your continuously optimized plan, products, process, and people will help sustain outcomes. In summary, your desire to serve with humility, add value continuously, and optimize the outcomes will ensure sustainable results. Additional Reading VUCA Tools for a VUCA World by Ann Deaton.

0 Comments

The Fourth S – Scale

You are ready to Scale your business if you’ve already:

Manpower Do you have the right and enough resources? Money Do you have enough capital to achieve your objectives now and in the future? Material Do you have enough material to produce what you need now and in the future? Method Do you have suitable & practical plans, policies, and procedures to scale your business? Machine Do you have tools and machines to produce products & experiences? Marketing Do you have the platform to promote your services when the time is right? Measurements Do you have the basic KPIs to measure yourselves & partners against your goals? Mother Nature Do you have protection against most uncontrollable events? You may notice that your processes and tools may need slight to moderate modifications to accommodate successful growth. Here are the key elements you need to pay attention to: Securing and Growing Revenues Securing revenues will be easy because you already created a product or service with a solid competitive advantage over rivals. Furthermore, addressing the following points will help you scale your topline more successfully:

Reinvesting in Innovation & Technology Innovation is the lifeline for your business, where you identify and formulate how you will reach higher brand equity with a competitive advantage by creating new Intellectual Properties. What percentage of your revenues are you investing back into your company for innovation, research, and development? Is it sufficient for the next-generation products and services? On the other hand, you don’t want to spend for the sake of spending it, right? Watching for the Capital Expenses You’ve managed to scale the top line and invest back in your R&D healthily, but it won’t prevent the company from getting into trouble if your expenses exceed your revenues. The irony is the more you scale the business, the faster you could get into trouble. I had one such client that they didn’t even realize they were on the verge of bankruptcy because of that. One such expense is capital expenses. Though they are more controlled and come with depreciation benefits, decision-makers must ask themselves if such expenditures are necessary. I’ve seen a company whose competitive advantage is in service yet; they kept their two SMT manufacturing lines and recently added six lean-lifts, all nearly costing them $16 million, the footprint of manufacturing and inventory room and inventory cost excluded. Instead, they could work with a PCBA manufacturer and get what they wanted, even at a lower product cost, while using this $16 million for further growth. This is where Make vs Buy decision-making comes into play. On the other hand, if your business relies on manufacturing and you can do so at high quality at the lowest cost, you may consider not only keeping it for your production but also changing manufacturing from a cost center to a profit center. Keeping your productivity at an optimum level with manageable labor shifts and enough equipment would be ideal for a company that can manufacture for others, even competitors, if and when it makes sense. This also helps minimize manufacturing downtime, reduce equipment amortization costs on products, and increase revenues simultaneously. Watching Out for Operating Expenses The same rules apply to operating expenses. You want to keep your internal resources occupied for impactful outcomes. You don’t want to keep them for the sake of doing so. If you can outsource mundane tasks, you should do so. Not only does it save money for the company, but it keeps the employee morale up because they can focus on more important matters. On the other hand, outsourcing too many people requires more internal resources to manage outside help, which would double the cost. Keeping in-sourcing vs outsourcing is a delicate balance. You decide what makes sense overall. Scaling requires measured redundancies in the system. What happens if a bus hits your crucial employee who is the only one with tricks of the trade? The knowledge needs to be passed on to the next generation along with proper documentation. Then, hire a few inspirational and capable resources and get a lot done. Lastly, Don’t Do These Common Mistakes!

Additional Reading Crossing the Chasm, Marketing and Selling Disruptive Products to Mainstream Customers by Geoffrey A. Moore Scale or Fail: How to Build Your Dream Team, Explode Your Growth, and Let Your Business Soar by Allison Maslan Scaling Up for Building Strong Company by Verne Harnish The Third S – Standardize

You Strategized and then Simplified your products and business processes. Before you Scale them, I highly recommend you Standardize them, as standardization has significant benefits for your business. Consider the following:

Standardize Your Product Product standardization helps you achieve a lower product cost by taking advantage of economies of scale and negotiating better terms for your raw materials and PPV (Purchase Price Variance). Your in-house manufacturing facility and outsourcing partners use the same raw materials across many SKUs and utilize the same machines and techniques in manufacturing. Further cost benefits also come from assembly and manufacturing efficiency since product variation is minimal. Finally, the learning curve is more exponential, substantially reducing the risk of failure. All in combination, you reduce your OPEX (operating expenses) and variable costs. Your standardization efforts may help you improve your competitive advantage since your total cost decreases. With a bit of innovation, you gain a stronger top-line (revenue) as your brand gains more equity advantage over others. An example from the past -- we used the same printed circuit assembly for different SKUs, even prestigious brands. While consumers saw different shapes, colors, and brand products, the internal components and designs of these products were the same. This allowed us to leverage economies of scale, reducing our product material cost to a minimum. Our product development costs decreased since the engineers standardized the electronics module in size, fit, form, and function; we could spend our energy on mechanical and industrial design aspects instead. Overall, we launched our products faster, accelerating revenues, and designed more value-added upgrade products with the same resources, which is even more to our top-line. Standardize Your Business Process Business processes can be standardized after they’re simplified, similar to product standardization. This means you build the simplest viable and repeatable process that delivers results. It supports your business and provides results efficiently and effectively. Process standardization removes ambiguity among team members about expectations and business outcomes since they follow an already established set of rules for accomplishing tasks. This, in return, improves your employee morale, overall productivity, and delivery quality. Business Process Standardization goes hand-in-hand with Product Standardization, particularly regarding the DFx (Design For excellence) efforts with subsets such as Design for Commonality (I call it commonality via modularity) as we discussed above, Design for Assembly, Design for Manufacturing, Design for Testing, Design for Quality, Design for Supply Chain and so on… The ultimate goal in DFx is building the best working business process in its simplest form that gets standardized so your employees follow those guidelines. Standardize Your Documentation Talking about the guidelines… your standardized documents will support and institutionalize your standardized process. Initially, writing playbooks and standardizing them takes time. But, in the long run, it saves time, reduces errors, and provides consistent information and guidelines. Newcomers to your company can refer to these documents and follow the guidelines, especially without a well-functioning buddy or mentorship program. Let’s not forget the version controls to provide clarity for changes. Otherwise, we create more chaos than necessary. An example from the past – My team developed and implemented the best business practices in Product Management, PLM, Business Strategy, Operations, Leadership, DFx, Make vs Buy decision-making, SIOP, and Strategic Procurement at our clients. One of our clients sent us a thank you letter following the COVID-19 outbreak, explaining how grateful they were for the robust system we left behind with a written playbook that new employees could learn from and follow. They kept delivering strong results quarter after quarter, even during and after the pandemic. They said their financials have been more robust than ever. Take Standardization seriously, as it plays a crucial role in delivering sustainable results. We will cover this again in the Sustain section yet to come. Also, standardizing the product, process, and documentation makes credentialing, regulatory compliance, and audits much more straightforward. As a result of these well-implemented steps, we passed the ISO 9001 audit in under two hours instead of taking days. Email us for expedited results. Additional Reading for this section: Process Standardization A Complete Guide – 2021 Edition by The Art of Service – Process Standardization Publishing Process Mapping and Process Improvement Standardization Workbook: Standardize The Continuous Improvement Process With Standard Operating Procedure Templates by The Lean Culture Organization The Second S - Simplify Last week, we discussed the importance of doing due diligence through corporate, business, and product strategy and putting together a comprehensive business plan before starting to deliver results. Now, you are probably thinking about scaling up your company as soon and sustainably as possible. Before doing so, however, have you considered that you might be scaling up your problems along with your business? Because that is the inevitable outcome if you don’t Simplify first. You hire people to fix the issues, add band-aid solutions, buy software platforms to add more complexity and interoperability, and in the end, you get held hostage as changing them in the future costs you even more. Simplicity is essential to achieving and sustaining real success, and many executives miss it because they believe time is money and want to keep moving forward. They don’t have time to “deal with it” or think it’ll be somebody else’s problem in the future. Here’s the antidote to break this perpetual pattern:

Simplify your product You might have experienced being in a restaurant with over 300 menu items. Reading through the menu, choosing what you want becomes a daunting task rather than a pleasure. How would you like to create that level of complexity for your internal and external customers? Remember, the most appreciated products are designed around a few substantial benefits rather than a boatload of features that serve little to nothing but lessen the core value proposition. Once you accept that you can’t make 100% of people happy, your focus can move to delight 80%-90% of your target segment. Remove the unnecessary features. Instead, focus on real value-added benefits without compromising quality, form, or function. Let your message become more targeted, concise, and explicit. Simplifying products also help you reduce costs since you use fewer parts and variations. This means less risk of failure as well. Your buying power also improves because of the economies of scale. Kill the noise! I had a client who works with 16,000 suppliers around the globe. They didn’t need 15,000 of them. Keeping old SKUs alive for a little more revenue or to keep all clients happy is a common mistake many sales and engineering-driven companies make. Decide where you draw the line. My practical suggestion is cutting off the long tail that contributes 10% of the revenues after you lay out the Pareto. You can be more aggressive and do so for the 20% if the tail length is substantial. Otherwise, you’re locking your engineering resources and overburdening your operations, manufacturing, supply chain, quality control, marketing, and sales teams, which are dealing with the noise on a daily basis. Many of my clients suffer from high operating expenses that constrain their healthy growth and negatively impact their EBITDA. Example from the past-- As part of the product simplification process, we introduced modularity (minimally viable product), where the engineering team could use the same electronic components and modules with different casings to commercialize variations of the same product that would address the needs of various market segments. We EOL (End of Life) 23% of SKUs within months. The revenues increased by showing the value proposition more clearly. The margins improved from 11% and stabilized at 29% by reducing the cost of internal parts due to economies of scale, lowered returns by fewer failing parts, and tighter quality control processes over fewer SKUs. Simplify your business process and workflow Simplifying business processes and workflow is complicated since achieving such a goal requires a conscious effort from people at all levels. It’s challenging for those who’ve been performing their task in a particular fashion for many years. Although possible, patterns and habits developed over the years are difficult to break. The first step to simplifying business processes and workflow is stating every step of the current business process and workflow. I usually use Visio to visualize the end-to-end process and follow the checklist:

You now have a clear visibility of your end-to-end business flow. You can then decide the best time to transition to the improved version. My philosophy is there is never a better time than now. The change will be painful regardless. One significant advantage of doing it earlier is it’ll make your lives easier and faster; it’ll cost you less now, so you can start reaping the benefits. Having said all that, take whatever precautions are necessary to reduce the impact caused by interruptions to your business. Example from the past—As part of our client's business workflow simplification process, we reduced the product concept-to-launch period from 26 weeks to 16 weeks. The impact of these extra 10 weeks continuously reduced their development cost per project (margin impact), increased their revenues since they could take more projects using the same number of resources (revenue and OPEX impact), and increased business turnover year after year (EBITDA impact). Simplify your governance You have already done the groundwork of governance by determining KPIs (Key Performance Indicators), setting RACI (Responsible, Accountable, Consulted, Informed), and clearly defining R&R (Roles and Responsibilities) during the Strategize step. What you need to add now is how to ease and streamline the decision-making process without unnecessary or no-value-add red tape. The key questions you need to ask yourself:

Tony Robbins has a great saying, “Energy Flows Where Focus Goes.” Your job here is to bring focus governance simplification for healthy and sustainable growth while encouraging inclusiveness, better communication among cross-functional teams and ranks, rewarding innovation and ideas for positive change for overall improvement. A final note on Simplification – Do it at every opportunity as part of your continuous improvement. Reach us if you want support and expedite the results. Additional Reading for this section Simplify: How the Best Business in the World Succeed by Richard Koch and Greg Lockwood The Basics of Process Mapping by Robert Damelio The Basics of Process Improvement by Tristan Boutros |

AuthorJames Stanford Archives

January 2024

Categories

|

Services |

Company |

|

RSS Feed

RSS Feed